While moulds are an important part of the environment, its growth indoors can cause serious health problems. Unexpected events, like leaks from pipes and flooding from storms, can create standing water, which allows mould to grow in just 24 to 48 hours. Because of its fast spread, mold can be nearly impossible to prevent. That’s why it's important to focus on controlling its path—in the safest possible way.

Remediation specialists need the tools to not only keep themselves safe, but also the people in surrounding areas. With the proper protective equipment and the necessary tools, contractors are able to meet standards and safety regulations to effectively protect against infections and mould induced reactions.

Here are key tools remediation specialists will need to get the job done safely:

Personal Protective Equipment

Contractors rely on personal protective equipment (PPE), like respirators, gloves, and fitted goggles combined with high-efficiency particulate absorbing (HEPA) filters, cleaners, wet vacuums, and disinfectants to effectively and safely remediate mould.

Beyond PPE, contractors also need to take additional steps to contain harmful particulates and protect air quality. Taught by various organizations, like the IICRC, industry training and best practices often involve the following products: reusable containment barriers and negative air machines.

Reusable containment barriers

To protect others in and around the affected area, it’s important to isolate the contaminated area by closing off HVAC grills, sealing off cracks and crevices, and setting up containment barriers.

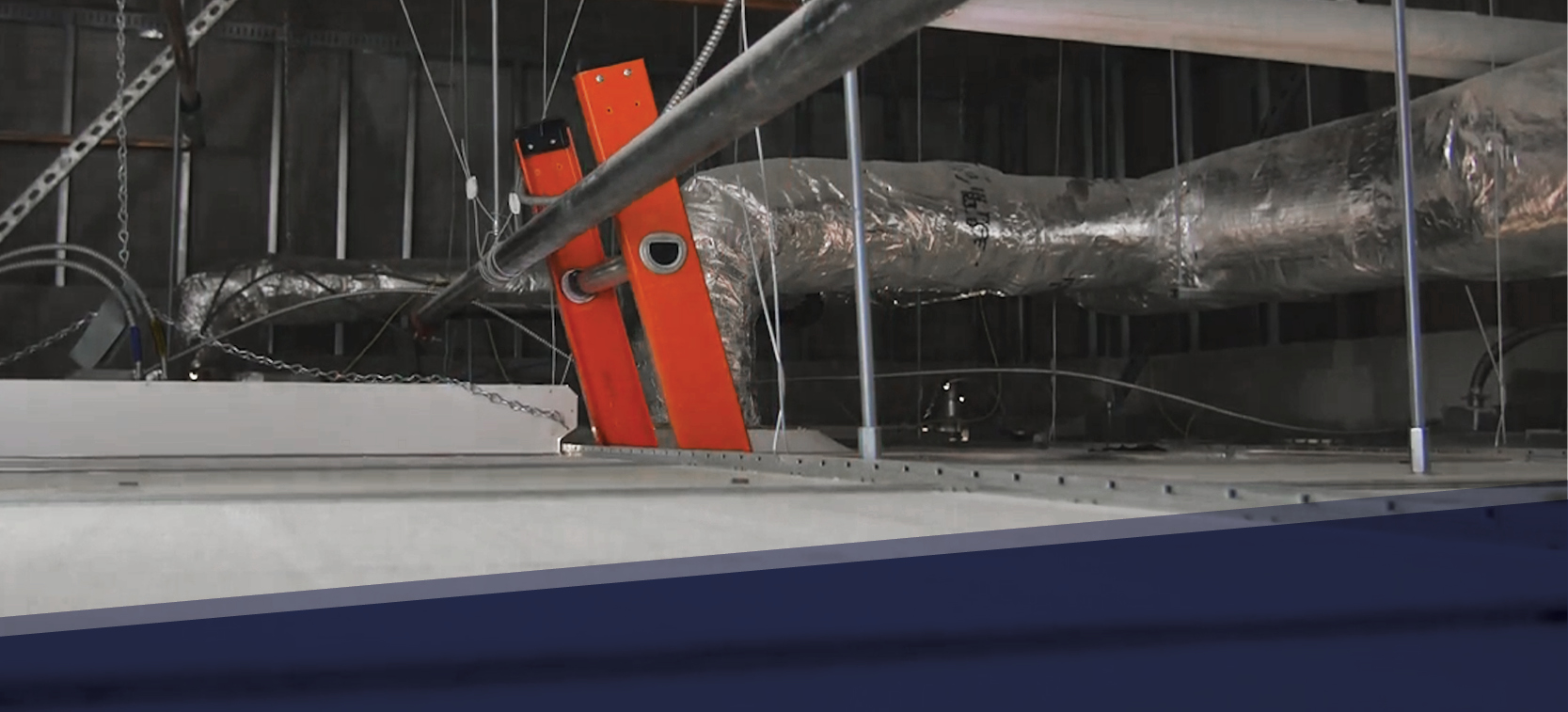

Traditional containment has been done by using poly sheeting and drywall with insulation. But, these materials are not reusable and are often disposed of at the end of the project. With the rising cost of construction-related materials and the huge labor shortages, companies are turning to reusable containment barriers, like our SHIELD WALL™ solution. It’s quick and easy to install and can be used over and over again.

By combining the containment walls with air filtration devices and a differential pressure monitor, remediation experts can create a negative pressure environment within the contained area for a complete containment solution.

Portable HEPA Filtration System

Portable air scrubbers—or negative air machines—are used in conjunction with containment to remove contaminated air from a sealed containment area through ductwork. The filtered air is exhausted outside of the contained area, creating negative air pressure inside.

There are several varieties of air filtration devices available on the market today, but it’s important to know which device is the most effective option. The best choices are units equipped with true HEPA filters. A true HEPA filter can capture 99.97% of 0.3-micron particulates, including mold spores, dust, and other allergens, and an even higher percentage of larger particles.

At Abatement Technologies, our PRED750 can be used alone or in conjunction with central air filtration to effectively remove harmful particles from the air. The portable air scrubber is equipped with a high-efficiency HEPA filter and is the most mobile HEPA filtration device in its class.

Want to learn more about Mould & Indoor Air Quality?

In our recent white paper “Mould & Indoor Air Quality: An Abatement Technologies White Paper,” we discuss:

1. How mould grows

2. The effects it can have on our health

3. Steps and standards for mould remediation

4. And the tools needed for the job

Download the white paper here.