DISASTERRESTORATION

- AIR CHANGE CALCULATOR

- US AND CANADIAN WORKPLACE SAFETY REGULATIONS REQUIRE SAFETY CERTIFIED ELECTRICAL EQUIPMENT

- FACTS ABOUT TRUE HEPA FILTRATION

- FAQs

- INSURERS APPROVE PORTABLE AIR SCRUBBERS

- NRTL PRODUCT SAFETY CERTIFICATION

- SAME DAY EQUIPMENT SHIPMENTS

- THINGS YOU NEED TO KNOW ABOUT HEPA FILTRATION

- UL94HB FLAMMABILITY REQUIREMENTS

- MODES OF OPERATION

AIR CHANGE CALCULATOR FOR DISASTER RESTORATION

US AND CANADIAN WORKPLACE SAFETY REGULATIONS REQUIRE SAFETY CERTIFIED ELECTRICAL EQUIPMENT

OSHA AND CAN/CSA REQUIRE NATIONALLY RECOGNIZED TESTING LABORATORY (NRTL) CERTIFICATION OF ELECTRICAL DEVICES USED IN AMERICAN AND CANADIAN WORKPLACES — DOES YOUR COMPANY'S EQUIPMENT COMPLY?

OSHA safety regulations in the U.S. and CAN/CSA regulations in Canada require all electrical device models used in the workplace to conform to applicable safety standards. This means that the device must be submitted by the manufacturer to an OSHA Certified Nationally Recognized Testing Laboratory (NRTL) such as UL, TUV, ETL or CSA for the specified certification testing.

HEPA filtration devices such as portable air scrubbers and axial and centrifugal air movers must conform to the UL507 “Fans and Blowers” standard. Devices with plastic cabinets (enclosures) that contain energized electrical components must be NRTL certified to conform to UL flammability standards (typically UL94HB) as well.

The sad fact: a significant number of the HEPA filtration devices, air movers and other devices sold and in wide use today are not NRTL certified. This problem appears to be particularly prevalent with devices imported from Asia, but applies to some products made right here in North America as well. It’s possible that some of these products might comply if submitted to and tested by an NRTL, but it appears likely that at least some would fail.

It costs money to design and build products that can conform to these safety standards. Uncertified devices may be available at a lower price, but isn’t that like playing Russian roulette? Without the proper safety certifications how can you possibly know whether or not the product is safe? With all that could be at stake is the chance to perhaps save a few bucks up front a risk that you can really afford to take?

At Abatement Technologies product safety is one of our paramount concerns. That’s why each and every Abatement Technologies portable air scrubber and air mover model sold in the U.S. has been tested by a Nationally Recognized Testing Laboratory (NRTL) and certified to conform to UL507. All models made with polymer cabinets have also been NRTL tested and certified to conform to stringent UL94HB flammability standards.

All NRTL certified products must have an NRTL certification label attached to them to show that they are compliant. It might be a good time to take a few minutes to inspect your equipment and check for the labels. If they are not there it might be time to call your supplier and find out why. Or, it might be time to look for another brand that is certified.

FACTS ABOUT HEPA FILTRATION

According to the latest 2003 CDC Guidelines for Environmental Infection Control in Healthcare Facilities, HEPA filtration is required for the capture of microbial spores and other contaminants that can potentially cause fungal infections and Aspergillosis. All PREDATOR® and HEPA-AIRE® Portable Air Scrubbers are equipped with high-efficiency, HEPA filters that are tested and certified to remove 99.97% (9,997 out of 10,000) of particles as small 0.3 microns (0.000012-inch) in size. To put this in perspective, the diameter of fungal spores is typically five to 25 microns while a human hair is 50 to 200 microns.

Testing and Certification by Independent National Laboratories

Abatement HEPA filters meet Institute of Environmental Sciences and Technology IEST-RP-CC001.3 standards for Type A 99.97% efficiency HEPA filters. To meet this standard, each and every completed Abatement HEPA filter must be tested for leakage and resistance, to detect any leaks in the media or between the media and the frame or other problems that can compromise the integrity of the completed filter. Test results must be shown on a label on the filter frame. Filter frames should be metal. The 2003 CDC Guidelines state that: “Wood (HEPA frames) can compromise the air quality if it becomes and remains wet, allowing the growth of fungi and bacteria,” and recommends replacing these filters with metal-frame filters. Filters should also meet UL900 Class II flammability requirements.

How often do Abatement HEPA filters need to be changed?

The size and concentration of airborne contaminants, temperature, humidity conditions and duration of use determine how often filters need replacement. As the filters become loaded with particulate matter, the airflow capacity of the unit decreases and the static pressure differential across the filter increases.

Abatement PREDATOR and HEPA-AIRE Portable Air Scrubbers are equipped with easy-to-read filter change indicator lamps that illuminate when filters should be replaced. Unlike gauges, these lamps do not require operator interpretation or calculations. Average filter life (with continuous operation):

-

- • Primary filter: 1 day

- • Secondary filters: 3-7 days

- • HEPA filter: 800 hours

What are the total cost-savings of using Abatement Portable Air Scrubbers and HEPA Filters versus the competition?

Abatement Portable Air Scrubbers and high-efficiency HEPA filters can potentially save users up to $10,000 or more over the life of the unit compared to other systems, including low-priced (and generally low-quality) “economy” products. Four main factors contribute to these savings:

- Longer filter life because the filters provide exceptional dirt-holding capacity

- Lower replacement filter costs

- Lower labor costs due to higher productivity

- Minimal downtime. By any measure, this is an excellent return on investment.

What does the term HEPA mean?

HEPA is an acronym for "High Efficiency Particulate Air" or "High Efficiency Particulate Arrestance." This acronym refers to a filter that is manufactured, tested and certified to meet Institute of Environmental Sciences and Technology (IEST) construction, performance and certification standards as currently published in IEST RP-CC001.3.

What is it that makes HEPA filters so efficient?

The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interception and inertial impaction. To qualify as a Type A HEPA filter, the filter must capture at least 99.97% (9,997 out of 10,000) of particles 0.3 microns in size–about 300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is like stopping a cotton ball with a door screen.

Are all filters made with HEPA filter media HEPA filters?

Manufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. Serious filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. Even the tiniest pinhole leaks in the media or breach of the seal between the media pack and the filter frame can cause the filter to fail IEST requirements. The testing requires very specific procedures using a thermally generated mono-dispersed aerosol and a laser particle counter. Some regulations also require field-testing by the user prior to going into service and periodically thereafter.

Why is the testing done with a 0.3-micron particle size test aerosol?

Filter efficiency studies have shown that 0.3-microns is the "Most Penetrating Particle Size (MPPS)" for HEPA filter media. Efficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are typically more easily trapped, or intercepted, by the media. Smaller particles often lack sufficient mass to penetrate the media.

Is a "HEPA-Type" filter the same as a HEPA Filter?

No. In fact, the differences are huge. According to the American Lung Association, filters classified as "HEPA-type" filters may capture as little as 55% of 0.3-micron particles (5,500 out of 10,000). By this definition, the true HEPA filter could be more than 1,800 times as efficient as the "HEPA-type" filter.

Does HEPA filter efficiency decrease as the filter gets dirty?

No. Unlike electronic air cleaners and other air purification technologies that experience substantial loss of efficiency as they become dirty, exactly the opposite typically happens with HEPA filters. In fact, the dirtier a HEPA filter gets, the more efficient it can become.

FAQS ABOUT WATER RESTORATION SOLUTIONS

Frequently Asked Questions about Abatement Technologies® Equipment for Water Restoration Professionals

When would you use a centrifugal air mover vs. an axial fan air mover?

The air outlet of a centrifugal air mover, such as Abatement Technologies’ RAPTOR® Series Air Movers, is low and parallel to the floor so it places maximum air flow to where water has accumulated. An axial fan air mover moves large volumes of air and is used in vortex drying procedures.

Can you stack several raptor centrifugal air movers and daisy-chain them for operation off of a single electrical wall socket?

Yes, up to three RAPTOR Air Movers can be stacked and interlocked securely during operation or storage. Up to four units can be daisy-chained to operate on a single 15 amp circuit.

What is the purpose of using a moisture meter for water damage restoration?

Delmhorst Moisture Meters are used to measure, monitor and record moisture levels in a water-damaged structure as it goes through the drying process. Using a moisture meter is the only way to know with certainty if the structure is dry at the end of the drying process.

How can I create a protective containment barrier that is easy to set-up and can be configured for various enclosure sizes?

The ZipWall Containment Barrier is an easy-to-use protective barrier system that goes up in minutes without the need for special tools. The versatile ZipWall system adapts to various ceiling heights using telescoping, twist-lock ZipWall poles and spring loaded ZipWall jacks.

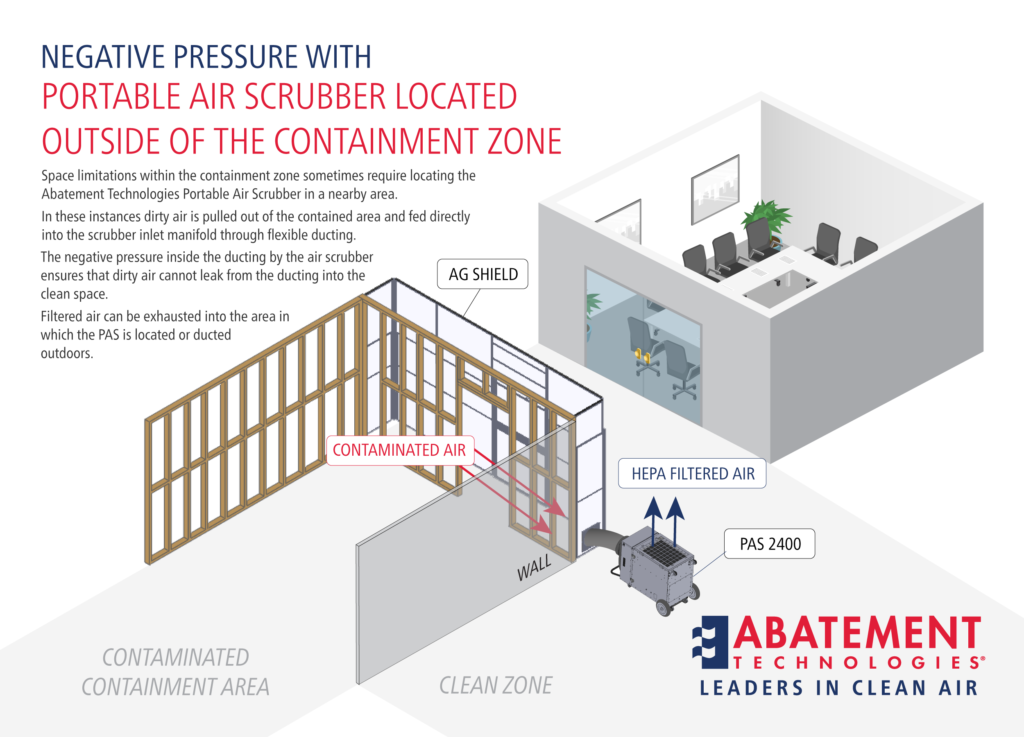

Why is negative pressure important?

A negative pressure environment will help to contain the construction dust and contaminants within the construction space. A negative pressure space eliminates the possibility of contaminants passing outside of the construction area through leaks in the construction barriers.

Can I order PPE from Abatement Technologies along with all of my restoration equipment and chemicals?

Yes. Along with a complete offering of equipment, products and chemicals for water restoration contractors , you can order PPE to help keep workers safe against biohazards and contamination.

How do I create a negative pressure environment using Abatement PREDATOR® and HEPA-AIRE® portable air scrubbers?

In order to create a negative pressure environment, more air must leave the space than enters it. First of all, the construction area must be walled off and Abatement Portable Air Scrubber(s) must be placed inside the construction area. Ductwork should be run from the system to somewhere outside of the construction area, preferably to the outside of the building. Since the air is HEPA filtered, it is not mandatory to exhaust air to the outdoors.

Which size Abatement portable air scrubber is needed for my current project?

Six or more air changes per hour (ACH) are recommended for effective air cleaning during construction and renovation work. To determine the amount of airflow and the number of PREDATOR or HEPA-AIRE PAS units required for your project, view the air change calculator .

How is the amount of airflow that must be removed from the containment zone to maintain negative pressure calculated?

The general rule of thumb is that at least 10% more air must be exhausted from the area than is supplied to it. For example, if 500 CFM is coming in through the facility HVAC system, then at least 550 CFM must be filtered and exhausted by the PAS.

What are the differences between Abatement portable air scrubbers and negative air machines?

We manufacture both types of products. Although they perform similar functions, they have distinctly different designs and markets. Big, boxy and heavy negative air machines with ‘no frills’ designs and hard casters are lower priced but are best suited for large projects in unoccupied facilities. Abatement PAS have a much lighter weight, upright design that makes them much more portable and easy to roll into and maneuver through tight spaces with minimal disruption to an occupied facility. Higher performance motors, blowers and filtration systems substantially improve airflow output and filter life and reduce operating costs. More elaborate controls and high tech stainless steel cabinets that look great and are easy to clean add to their ‘hospital friendliness’. Learn more about Abatement Technologies line of high-performance PREDATOR and HEPA-AIRE Series Portable Air Scrubbers .

How often do Abatement HEPA filters need to be changed?

The size and concentration of airborne contaminants, temperature, humidity conditions and duration of use determine how often filters need replacement. As the filters become loaded with particulate matter, the airflow capacity of the unit decreases and the static pressure differential across the filter increases.

Abatement Portable Air Scrubbers are equipped with easy-to-read filter change indicator lamps that illuminate when filters should be replaced. Unlike gauges, these lamps do not require operator interpretation or calculations. Average filter life (with continuous operation):

- Primary filter: 1 day

- Secondary filters: 3-7 days

- HEPA filter: 800 hours

What Abatement accessories are needed for negative air pressure applications?

PREDATOR and HEPA-AIRE Portable Air Scrubbers include an exhaust collar. Additional accessories needed are locking clamp(s), lay flat and/or flex ducts, additional collars and duct hose joints.

What is the warranty of Abatement portable air scrubbers?

All systems are covered by a comprehensive limited warranty to the original user against defects in materials and workmanship for a period of one year after date of purchase. This warranty excludes filters, which are consumable items that require ongoing replacement.

Does the MP3000 Mega-Pump provide HEPA efficiency?

No. The MP3000 MEGA-PUMP combines a high-capacity sump pump, vacuum system and a particle filtration system to separate solids into a stainless steel basket inside the 19 gallon stainless steel canister, while liquids are discharged through a standard 1.5” fire hose. Abatement Technologies does offer HEPA efficiency to remove hazardous particles from surfaces with the V8000WD Canister Style or V1300H Hip-Mounted HEPA Vacs.

FAQs about Product Safety Certification

You really emphasize the fact that Abatement products are tested and certified by ETL, a Nationally recognized testing Laboratory (NRTL). What are the requirements?

In the USA, OSHA safety standards for general industry and construction and the National Electrical Code require testing and listing (certification) of electrical products to applicable standards. It is important to note that this testing must be performed on an electrical device even if the individual electrical components used in that device are all listed or approved. Testing must be done by an OSHA-recognized NRTL, such as UL (Underwriters Laboratories), ETL (Environmental Testing Laboratories) or CSA (Canadian Standards Association). In Canada, The Standards Council of Canada has adopted standards for the Canadian Electrical Code developed on its behalf by the Canadian Standards Association (CSA). Third party testing from a laboratory or other organization, not NRTL-certified is not acceptable, even if such testing is done to applicable standards.

Why is NRTL certification so important?

Unless a unit is properly tested, users have no way of knowing whether it is properly and safely designed to meet the requirements of the applicable electrical codes. It is wise to require written vendor verification that the products you purchase are NRTL certified.

Aren't all air filtration products properly certified?

No. Unfortunately, many of the air filtration systems sold to and used by contractors, healthcare facilities and others are not certified, especially negative air machines.

Commonly Asked Questions about HEPA Filter Performance & Testing Requirements

What does the term HEPA mean?

HEPA is an acronym for "High Efficiency Particulate Air" or "High Efficiency Particulate Arsenate." This acronym refers to a filter that is manufactured, tested and certified to meet Institute of Environmental Sciences and Technology (IEST) construction, performance and certification standards as currently published in IEST RP-CC001.3.

How long have HEPA filters been in use?

The first HEPA filters were developed for the Atomic Energy Commission during World War II for use in facilities manufacturing components for the Manhattan Project (atomic bomb). These HEPA filters were originally designed to capture microscopic radioactive particles too small for effective removal by existing types of filters. HEPA filters used today are much more efficient and economical than the products made in the 1940's.

Where are HEPA filters used today?

HEPA filters are generally specified for applications where microscopic airborne particles or biopollutants could cause human health or product quality problems. Typical users include military, nuclear, pharmaceutical, electronics, biological and medical facilities.

What is it that makes HEPA filters so efficient?

The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interception and inertial impaction. To qualify as a Type A HEPA filter, the filter must capture at least 99.97% (9,997 out of 10,000) of particles 0.3 microns in size–about 300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is like stopping a cotton ball with a door screen.

Are filters this efficient really necessary for IAQ applications?

Laser particle counter measurements typically show that more than 99% of the particles suspended in indoor air are one micron (1/1,000,000 of a meter) or smaller in size. EPA calls these “lung-damaging” particles because they can lodge deep in the lungs when inhaled. The ability of HEPA filters to capture particles this small is what sets them apart from other types of filters. Regulations developed by EPA, OSHA, CDC and other federal, state and local government agencies responsible for human health and IAQ issues specify HEPA filters for asbestos, lead and mold abatement, TB and SARS isolation rooms and healthcare renovation projects.

Are all filters made with HEPA filter media HEPA filters?

Manufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. Serious filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. Even the tiniest pinhole leaks in the media or breach of the seal between the media pack and the filter frame can cause the filter to fail IEST requirements. The testing requires very specific procedures using a thermally generated mono-dispersed aerosol and a laser particle counter. Some regulations also require field-testing by the user prior to going into service and periodically thereafter.

Why is the testing done with a 0.3-micron particle size test aerosol?

Filter efficiency studies have shown that 0.3-microns is the "Most Penetrating Particle Size (MPPS)" for HEPA filter media. Efficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are typically more easily trapped or intercepted, by the media. Smaller particles often lack sufficient mass to penetrate the media.

Is a "HEPA-Type" filter the same as a HEPA filter?

No. In fact, the differences are huge. According to the American Lung Association, filters classified as "HEPA-type" filters may capture as little as 55% of 0.3-micron particles (5,500 out of 10,000). By this definition, the true HEPA filter could be more than 1,800 times as efficient as the "HEPA-type" filter.

Does HEPA filter efficiency decrease as the filter gets dirty?

No. Unlike electronic air cleaners and other air purification technologies that experience substantial loss of efficiency as they become dirty, exactly the opposite typically happens with HEPA filters. In fact, the dirtier a HEPA filter gets, the more efficient it can become.

WHY INSURERS SHOULD APPROVE THE USE OF PORTABLE AIR SCRUBBERS ON EVERY WATER DAMAGE REMEDIATION JOB

Insurance adjusters who do not authorize and approve the use of HEPA-filtered Portable Air Scrubbers (PAS) on all water loss jobs may want to rethink their position. Any water loss poses a significant opportunity for particle contamination and for microscopic bio-pollutants such as fungi (molds) and bacteria that thrive in wet indoor environments to proliferate. Even smaller water leaks or overflows of sanitary water can ultimately trigger fungal growth if wet materials are not promptly identified and thoroughly dried.

It is very important to note that the very activities undertaken to remediate the problem can increase the risks of air contamination. For example, as forced-air drying evaporates water from surfaces, carpet and other materials, contaminants such as fungal spores and ultra-fine dirt and dust particles are likely to be released into the air. Once aerosolized (suspended in air), workers exposed to these pollutants can inhale them. Particles stirred up during remediation also create housekeeping and cleanup issues that can increase the cost of the cleanup.

ANSI/IICRC Standard S500

The Clean Trust (formerly IICRC) has developed an ANSI-approved standard for water damage remediation. Now in its third edition, ANSI/IICRC S500-2006 Standard and Reference Guide for Professional Water Damage Restoration places water hazards into one of three contamination categories based on the quality of the water after it comes in contact with building materials:

- Category I – Water that originates from a sanitary source and does not pose substantial risk from dermal, ingestion or inhalation exposure.

- Category II – Water with a significant amount of contamination and the potential to cause discomfort or sickness if ingested by humans.

- Category III – Grossly contaminated water that can contain pathogenic, toxigenic or other harmful agents.

Types Of Indoor Air Pollutants

The Centers for Disease Control and Prevention (CDC) places air pollutants into three general categories: particulates, bio-aerosols, and volatile organic compounds (VOC), all of which may be released into the air during or following a water loss event.

Particulates

Particulates from building materials are primarily released into the indoor air after the event or during the remediation process as opposed to during the water loss event itself.

These commonly include dirt, drywall, VCT and concrete dust, fiberglass, carpet and asbestos fibers, sawdust, smoke particles, and metal fumes.

Larger, visible particles and smaller particles that agglomerate (clump together) will likely settle onto surfaces within minutes and remain there until physically removed by cleaning or vacuuming. These particles are not generally a respiratory health issue, because they are too heavy to remain aerosolized for very long.

Studies have shown, however, that more than 99% of the particles suspended in air are ten microns (0.0004 inches) or less in size. That’s five to 10 times smaller than a human hair and smaller than we can see with the naked eye. Particles and allergens this tiny are typically light enough to remain aerosolized for long periods of time and can readily spread through a building or home on air currents, and they are easily re-aerosolized when they do settle onto surfaces. They also pose the greatest potential health threat:

"While larger particles (those greater than 10 microns in diameter) get caught in the nose and throat, and are cleared naturally by coughing or swallowing, particles smaller than 10 microns in diameter are easily inhaled into the lungs. Of these, the smallest particles are most likely to reach the alveoli, where they can remain embedded for years, or in the case of soluble particles, be absorbed into the bloodstream. For this reason industrial hygienists often refer to them as ‘lung damaging particles’. -American Lung Association

NRTL PRODUCT SAFETY CERTIFICATION

Portable Air Scrubbers Comply with OSHA and CSA Electrical Safety Standards

Abatement Technologies® HEPA-AIRE® and PREDATOR® Portable Air Scrubbers have been tested by a Nationally Recognized Testing Laboratory (NRTL), and carry the associated marks certifying that they comply with applicable OSHA and CSA electrical safety standards.

Required Testing and Certification of Electrical Products

In the USA, OSHA safety standards for general industry and construction and the National Electrical Code require testing and listing (certification) of electrical products to applicable standards. It is important to note that this testing must be performed on an electrical device even if the individual electrical components used in that device are all listed or approved.

Testing must be done by an OSHA-recognized NRTL, such as UL (Underwriters Laboratories), ETL (Environmental Testing Laboratories), TÜV SÜD, or CSA (Canadian Standards Association). In Canada, The Standards Council of Canada has adopted standards for the Canadian Electrical Code developed on its behalf by the Canadian Standards Association (CSA). Third party testing from a laboratory or other organization, not NRTL-certified is not acceptable, even if such testing is done to applicable standards.

Why is NRTL Certification Important?

Unless a unit is properly tested, users have no way of knowing whether it is properly and safely designed to meet the requirements of the applicable electrical codes. It is wise to require written vendor verification that the products you purchase are NRTL certified.

Aren't All Air Filtration Products Properly Certified?

No. Unfortunately, many of the portable air scrubbers and air filtration systems sold to and used by contractors, healthcare facilities, and others are not certified. It is, therefore, impossible to know whether such products are safe or perhaps placing workers at risk.

Hurricane Emergency Water Damage Restoration Equipment and Flood Supplies for Professional Disaster Restoration Contractors

Abatement Technologies® Offers Same-Day, Rush-Order Shipments of Restoration Products to Help Mitigation Contractors Respond Faster to Water Damage Caused by Hurricanes, Flooding and Tornadoes.

After a hurricane has passed and the winds have ended, cleaning up the aftermath from water damage caused by heavy rain, catastrophic flooding and pounding storm surge is just getting started. With standing water in water-logged residential homes, commercial structures, retail malls and industrial facilities, it’s extremely important for disaster restoration contractors to take action now to mitigate water damage and reduce the likelihood of mold growth that leads to increased clean-up costs and health risks.

Same-Day, Rush-Order Shipments

To aid in the rapid response for flood restoration and storm clean-up services after a hurricane, Abatement Technologies offers same-day, rush-order shipments of all restoration products and flood supplies from fully stocked warehouses to anywhere in the country. Our inventories are large but move quickly. Buy now to make sure you have the hurricane response products you need! In addition to same-day shipments, Abatement offers next-day and second-day air shipping options for rush orders.

High-Performance Products to Dry Structures Faster

High-Performance Products to Dry Structures Faster

Abatement’s line of state-of-the-art, high-performance equipment, products and chemicals dry structures faster, improve productivity and help water loss restoration contractors return properties to their original condition sooner. Abatement’s restoration solutions include products developed by our engineering team as well as carefully selected manufacturers of other equipment and consumables used by restoration companies every day.

Restoration products include:

- RAPTOR® AIR MOVERS - High-velocity, high-volume air movers for structural surface drying

- AQUATRAP® AT150RS & 250RS DEHUMIDIFIERs - LGR dehumidifiers remove significant amounts of water at all temperatures for unsurpassed structural drying power

- PREDATOR® & HEPA-AIRE® PORTABLE AIR SCRUBBERS - Capture airborne particles and mold spores released during remediation and clean-up operations; Help eliminate odors

- HEPA-AIRE® WET/DRY VACUUMS - Canister-style wet/dry and portable hip-mounted HEPA vacuums to clean surfaces

- DELMHORST METERS AND ELECTRONIC INSTRUMENTS - Essential instruments to measure moisture levels, determine estimated electrical loads and measure particles

- PERSONAL PROTECTIVE EQUIPMENT - Protect workers in potentially hazardous environments

Water Restoration Specialists Can Help You Respond Quickly to Your Customers

Abatement Technologies’ national restoration team is available to help you make the right equipment and chemical choices, and to get your shipments to where they are needed – fast! Fulfilling product demand from contractors and remediation specialists providing disaster relief from hurricane water damage is our top priority. Make sure you have the hurricane response products you need now by contacting the national restoration team at 1-800-634-9091.

THINGS YOU NEED TO KNOW ABOUT HEPA FILTRATION & HEPA FILTRATION DEVICES

HEPA: An Essential Restoration Tool

Disaster losses and the facility restoration process commonly involve the release of a wide array of contaminants into the air including microscopic bio-pollutants, larger, visible particles and unpleasant odors. Portable HEPA Filtration Devices (HFD) that can effectively and efficiently capture them can provide one of the most important tools at a remediation contractor’s disposal, with numerous potential benefits, including:

- Enhanced productivity & work quality

- Improved work area health and safety

- Reduced cleanup time

- Limiting the area of contamination

- Increased customer satisfaction

- Faster job clearance & re-occupancy

- Reduced risk of re-contamination or call-backs

The objective of this paper is to address some common questions about HEPA filtration and portable HFD and to help users derive maximum benefit from them.

What Is A “True” HEPA Filter?

HEPA (High Efficiency Particulate Air) filters, also known as absolute filters, are much more efficient than other types of filters for removing microscopic particles from the air. By common definition a HEPA filter must provide 99.97% minimum efficiency during use. In other words, no more than three out of10,000 particles (0.03%) of the 0.3-micron particles pulled in can pass through. Filters must meet Institute of Environmental Sciences and Technology (IEST) Recommended Practices that cover filter media, filter media testing, filter design, construction and labeling, and completed filter testing.

Are All HFD Equipped With True HEPA Filters?

HFD and the filters used in them can apparently fall well short of HEPA performance based on various industry studies and in-field testing. The differences can be much larger than they perhaps seem. Compared to HFD with true HEPA efficiency a 99%-efficient HFD will have over 30 times more leakage, a 97%-efficient HFD 100 times more leakage and a 95%-efficient HFD over 165 times more leakage!

What Causes Less-Than-HEPA HFD Efficiency?

Some of the more common causes of reduced filtration efficiency can include:

• Each completed filter was not individually efficiency-tested.

The use of true HEPA media is no guarantee that the finished filter will be HEPA efficient because a large percentage of completed HEPA filters require repairs to fix problems such media damage or improper sealing between the media pack and filter frame. Without testing these problems cannot be found and corrected prior to filter shipment and use. In particular, a low percentage of the aftermarket filters in use today are individually tested per IEST requirements.

• The filter was not tested at the proper airflow.

Completed filters tested at airflows far below the rated airflow of the device in which the filter is used may not provide HEPA efficiency in use. The fact that a filter meets HEPA standards when tested at 500cfm or 1,000cfm airflow doesn’t mean it will when operated at 1,500cfm or 2,000cfm.

• The filter was not made with micro-glass HEPA media.

Some HFD “HEPA” filters are built with synthetic media that has an electrostatic charge applied to it to enhance initial efficiency above 99%. In-use efficiency can be reduced substantially as moisture in the air begins to dissipate this charge. This can force users to replace a costly filter after (and possibly during) each job.

• The filter is HEPA- efficient but the HFD still leaks.

Use of a less-than-HEPA efficiency pretty much guarantees that HFD performance will be compromised, but use of a true HEPA does not ensure overall HEPA efficiency. Leakage elsewhere can significantly compromise the overall integrity of the device by allowing unfiltered air to bypass the HEPA filter.

ARE THE MOLDED PLASTIC FILTRATION UNITS YOU USE FIRE-SAFE?

Properly designed molded plastic cabinets can offer a number of user benefits over fabricated metal cabinets for portable filtration devices.

They are typically lighter, and quality molded products, and designs can be made more aesthetically pleasing. Quality molded products are more likely to maintain their appearance and shape over time, and less likely to damage objects they may bump against in use.

However, before buying a plastic molded product, users should look closely at whether that product has been properly tested and certified by a Nationally Recognized Tested Laboratory such as UL, ETL, or CSA, to ensure that it meets the UL94 flammability & flame spread requirements. If not, they could be risking that the device they are using – and possibly the job site – could go up in flames.

UL94 Standards

Not all plastic resins meet the UL94 standard, and some of those that do not can be highly flammable. If such a cabinet is exposed to a flame or to excessive heat it can potentially erupt into a fireball very quickly. And, cabinet resin is not the only UL94 requirement. The standard includes a number of other specific design requirements to protect sensitive electrical components from possible exposure and degradation due to excessive heat or flames.

Making a product that does meet the UL requirements may add cost; however, it also adds peace of mind, and it’s the right thing to do. That’s why the Predator™ molded-cabinet products sold by Abatement Technologies have been tested and certified by Nationally Recognized Testing Laboratory (NRTL) to meet UL94 requirements, and carry the ETL and ETLc safety-certification labels.

Is it really worth it to your business to take on the risks of using molded products that don’t?